Flow meters are, as the name suggests, devices that measure flow in a piped system. Depending on the application, flowrate is measured as either volume or mass. Flow meters can clamp onto a pipe and measure flow with a type of sensor placed inside the pipe or act as an all-in-one component, allowing fluid or gas to pass through their bodies as they measure. When shopping for flow meters, many people debate digital vs mechanical flow meters. What's the difference? In this post, we will look at what differentiates flow meters, including operation and displays.

Comparing Flow Meter Types

The first thing you need to know about flow meters is how they work. There are almost as many varieties of flow meters as there are applications for them, so we cannot possibly cover them all. Below are listed some of the most popular types of flow meters.

Differential Pressure Flow Meters

This category of flow meters, which represents about 20% of all the world's flow meters, measures differential pressure across an orifice where flow is directly related to the square root of the differential pressure measured. These meters use a primary and secondary element. The primary element produces a change in kinetic energy while the second element measures the differential pressure present.

Positive Displacement Flow Meters

Positive displacement (PD) flow meters measure a volume of fluid in a closed space, deliver it forward, and then fill that space again and repeat the process. This calculates the amount of fluid transferred. While all other types of flow meters measure some other variable and convert it into flowrate, PD meters measure the actual flow of liquid or gas. These flow meters are popular due to their accuracy.

Velocity Flow Meters

Velocity meters measure, as their name suggests, the velocity of a stream. By doing this, they are able to calculate volumetric flowrate. These are less accurate when flow is unsteady or turbulent.

Mass Flow Meters

These meters measure force that results from the acceleration of mass in a system. Instead of volume/time, these flow meters measure mass/time. Mass flow meters are typically used in chemical and gas applications.

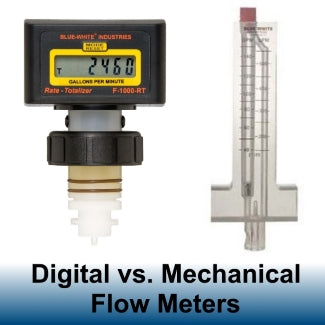

Digital vs Mechanical Flow Meters

When looking at whether you should get a digital or a mechanical flow meter, what you are looking at is the display (or readout). The display is what you look at to see what the flowrate is. This value is shown on a digital display or mechanically indicated through some non-electric means.

Mechanical

The most common type of mechanical flow meter is the classic rotameter. Rotameters are flow meters that measure the volumetric flow rate of liquid in a closed plastic or glass tube. They are a type of variable area meter and display flowrate using a floater that lines up with a measurement printed on the tube.

Rotameters require no external power or fuel, as they use the force of the fluid and gravity to measure flowrate. They are also simple and inexpensive, keeping costs low. This has made them extremely popular since the early 20th century. These advantages make rotameters ideal for applications that do not require precise flow measurement.

While these mechanical flow meters give the user a good idea of what the flowrate is, they are not very reliable or consistent. They have a heavy reliance on fluid viscosity, temperature, and type. Some liquids could even obscure the reading due to an obtrusive color or non-transparency.

Digital

In recent years, flow meters with digital displays and measurement methods have been standard in most industries. Digital flow meters take the data the mechanism is capturing and translate it into easy-to-read quantities that are much more reliable than traditional rotameter-style flow meters.

You can find almost every type of flow meter with a digital display. At the least, these meters are easier to read, but they can also provide improved accuracy with more complex interior workings. Because they have exterior power, they rely less on the pressure and temperature of fluid. This makes the readings they provide more reliable in applications that require precision.

The primary downside to digital flow meters is price. The technology that these meters rely on can be expensive. Unfortunately, high quality usually comes with a high price tag. Another slight disadvantage is the need to be plugged in, as outlets are not always easy to reach in industrial instances.

In conclusion, mechanical flow meters are great for low-precision applications on a budget and will provide accurate readings with certain fluids at specific temperatures. Digital flow meters will provide more reliable flowrate measurements at a higher cost. Not every application needs high precision, but for some it is paramount, so do your research before purchasing!

Commercial Industrial Supply carries high-quality Blue-White Industries flow meters. We provide several models of their digital and mechanical flow meters. Get a quote today!.